Meshtec is a modern high-tech company. We manage work with an intelligent system, using automated machinery such as powder coating, metal perforating, weaving, and robotic arms to increase production capacity.

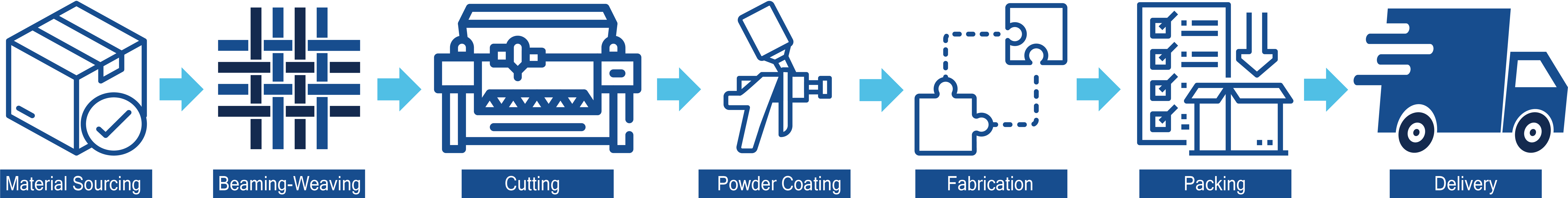

PRODUCTION

Every process is done in house with our expert team who are trained to control every single step throughout the design and manufacturing process to ensure quality.

MATERIAL RECEIVING

Raw materials are sourced from highly skilled manufacturers throughout Asia. Meshtec maintains strong strategic relationships with the suppliers of its most important raw material, stainless steel wire.

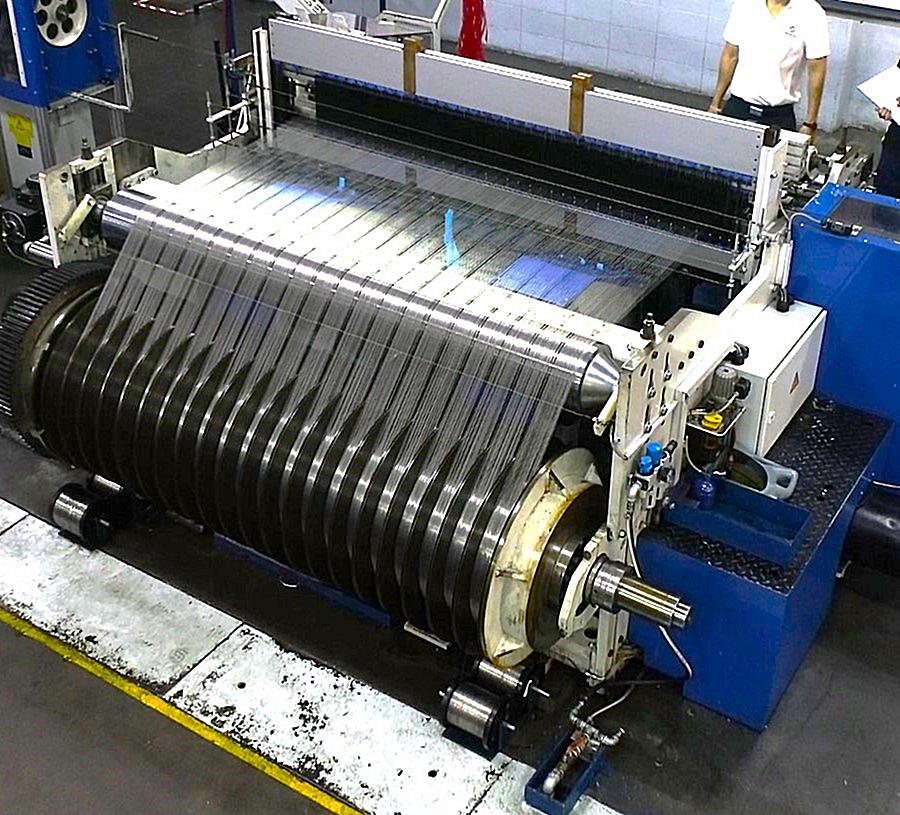

WEAVING EXPERTS

We have invested countless hours in research and development to create a completely unique plant configuration to produce the world’s highest quality high tensile stainless steel woven mesh.

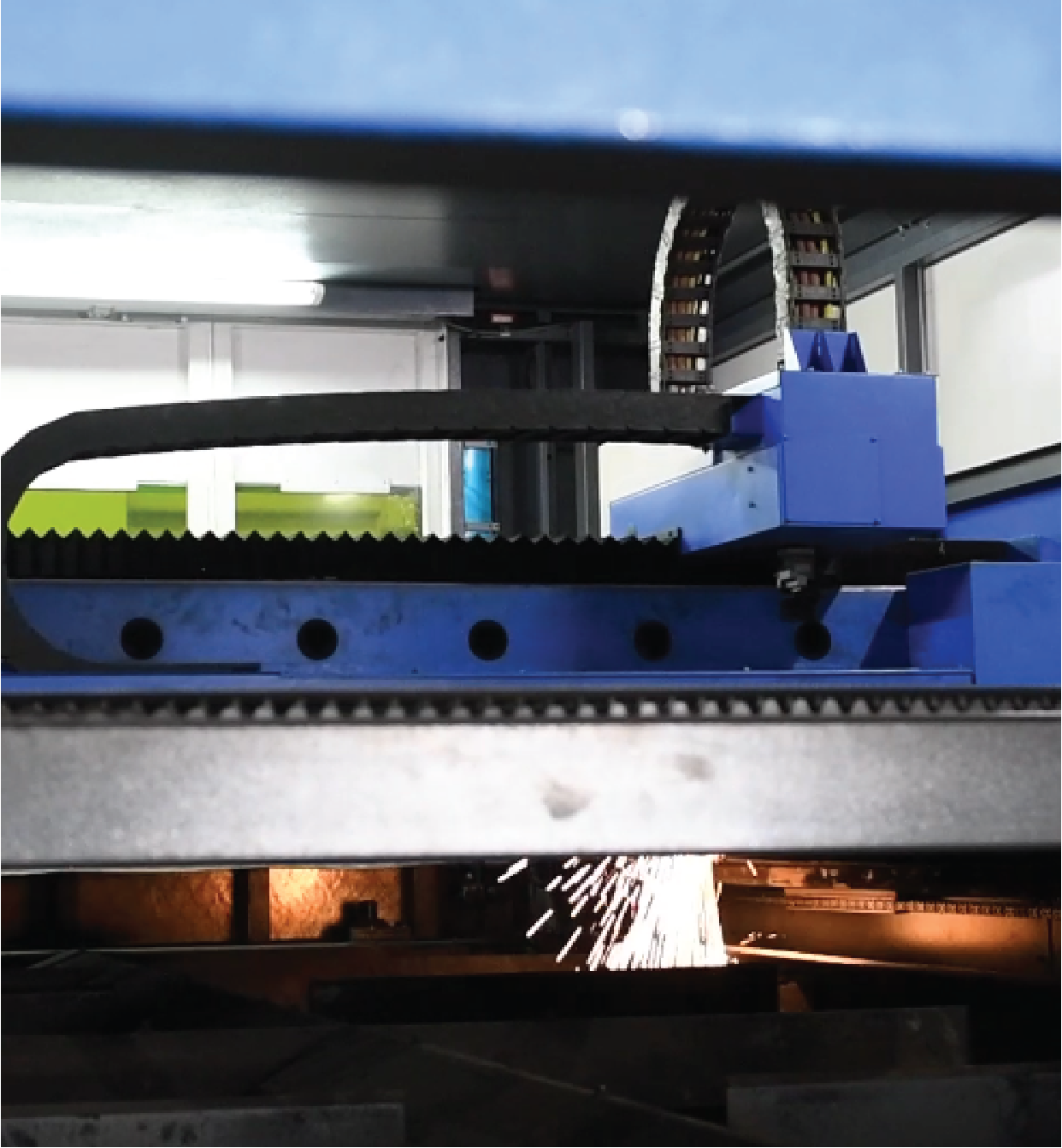

CUSTOMIZE CUTTING

The cutting process is done with specialized cutting equipment including a state of the art advanced laser - cutting machine allowing for high degree of customization of cutting to fit any shape of form.

SURFACE FINISHING

Specially designed in-line pre-treatment process and powder coating lines. Our mesh has been independently tested to withstand 10,000 hours of continuous salt spray – the equivalent of approximately 100 years of external exposure – with no visible signs of corrosion.

FABRICATION

Steps in the fabrication process include cutting the mesh and sash to the required dimensions and fixing the mesh into an assembled aluminum frame. Our premium quality product uses a wider frame, which allows a greater area of the mesh to be held within the frame, increasing security.

PACKING AND DELIVERY

High quality protective packaging is utilized for our entire product range. The various types of packaging is designed according to product type, as well as the mode of transportation to be used in distribution.

In an era where security is paramount, the need for robust and reliable security screens has never been greater. At Meshtec, we are proud to present a comprehensive one-stop OEM service that covers every facet of the security screen production process. From initial design concepts to the final logistics and delivery, we are your trusted partner in ensuring top-tier security screen solutions.

OEM FULL PRODUCTION CAPABILITIES

We're excited to share the groundbreaking strides we're making in security screens manufacturing industry, particularly in the production of high-tensile stainless-steel mesh and perforated aluminium. Our commitment to innovation and cutting-edge technology is not just a promise-it's the driving force behind our OEM full production

capabilities.

What sets us apart is our comprehensive Original Equipment Manufacturer (OEM) full production capabilities. From concept to completion, we handle every aspect of the manufacturing process. Our expert team works closely with clients to understand their specific needs, ensuring that the final product aligns seamlessly with their requirements.

INNOVATIVE DESIGN TAILORED TO YOUR NEEDS

Our journey begins with innovative product design. Our team of skilled product designers collaborates closely with clients to understand their unique requirements. Whether it's for residential, or commercial applications, we ensure that every design is not only functional but also aesthetically pleasing.

PRECISION WEAVING FOR UNPARALLELLED STRENGTH

The heart of our operation lies in the meticulous weaving process. Utilizing cutting-edge technology, we produce security screens with unparalleled tensile strength and durability. Our weaving experts pay attention to the finest details, ensuring that each screen meets the highest standards of quality and security.

UNVEILING MESHTEC’S IN-HOUSE POWDER COATING MASTERY

Our journey towards perfection begins with an in-house powder coating process that's at the forefront of technological innovation. Unlike traditional coating methods, our process is meticulously designed to ensure consistent, high quality results on every security screen that bears the Meshtec name.

Meshtec's powder coating facility boasts state-of-the-art technology that allows for precision and efficiency in every step of the coating process. From surface preparation to the application of the coating itself, our advanced machinery ensures a flawless and even finish, enhancing the overall appearance and performance of our security

screens.

IN-HOUSE FABRICATION EXPERTISE

Unlike many in the industry, we don't stop at weaving – we seamlessly transition into the fabrication phase. With an in-house fabrication team, we have complete control over the manufacturing process. This ensures that the security screens we deliver are not only of superior quality but also tailored to precise specifications.

STRINGENT QUALITY CONTROL MEASURES

Quality is non-negotiable. Our commitment to excellence is evident in our stringent quality control measures. Every security screen undergoes thorough testing and inspection, guaranteeing that it meets and exceeds industry standards. Your peace of mind is our priority, and our quality assurance processes reflect that dedication.

EFFICIENT PACKING FOR SAFE TRANSIT

Protecting our products during transit is as crucial as their production. Our packing experts employ efficient and secure packing techniques to ensure that your security screens arrive at their destination in pristine condition. We understand the importance of every screen, and our packing methods reflect that commitment to safeguarding your investment.

STREAMLINED LOGISTICS FOR TIMELY DELIVERY

Our one-stop service includes a streamlined logistics process that guarantees timely delivery. Whether you're a local client or situated across borders, our logistics team ensures that your security screens reach you on schedule. We value your time, and our logistics operations reflect our dedication to efficient and reliable service.

Choosing Meshtec means choosing a partner committed to delivering excellence at every stage of the OEM security screen production process. We understand that security is not just a product; it's a promise. With our one-stop service, you gain a trusted ally dedicated to providing seamless solutions–from design inception to the final delivery.

Businesses that will receive investment promotion must be important and beneficial business in the economic, social and security aspects of the country. Production business for export that use capital, labor or services at a high rate.

Meshtec is the world's leading industrial company about security doors and windows that have continued to grow in capital investment every year. We are supported and protected by Thailand board of investment (BOI) for importing machinery from leading countries such as a Powder coating line, Perforated automatic line, and weaving line. We also received support for the project of Sustainability "Solar rooftop saving energy project" to reduce energy use within the factory and be friendly to the environment.

Meshtec increase our production capacity, and cover all supply chain and customer needs along with ISO9001.As well as being able to create jobs for people in the community by recruiting employees to gain experience with us.

It is considered a successful growth for Meshtec to be able to carry out production and export operations efficiently with sustainable.